Quality as a Top Priority

In the world of electronic manufacturing, quality is never an option—it’s a necessity. At EMC SRL, our commitment to excellence translates into a rigorous quality analysis and control process, utilizing the most advanced technologies: AOI (Automated Optical Inspection) and X-Ray. Every electronic board that leaves our labs is the result of meticulous inspections, designed to ensure reliability and high-level performance.

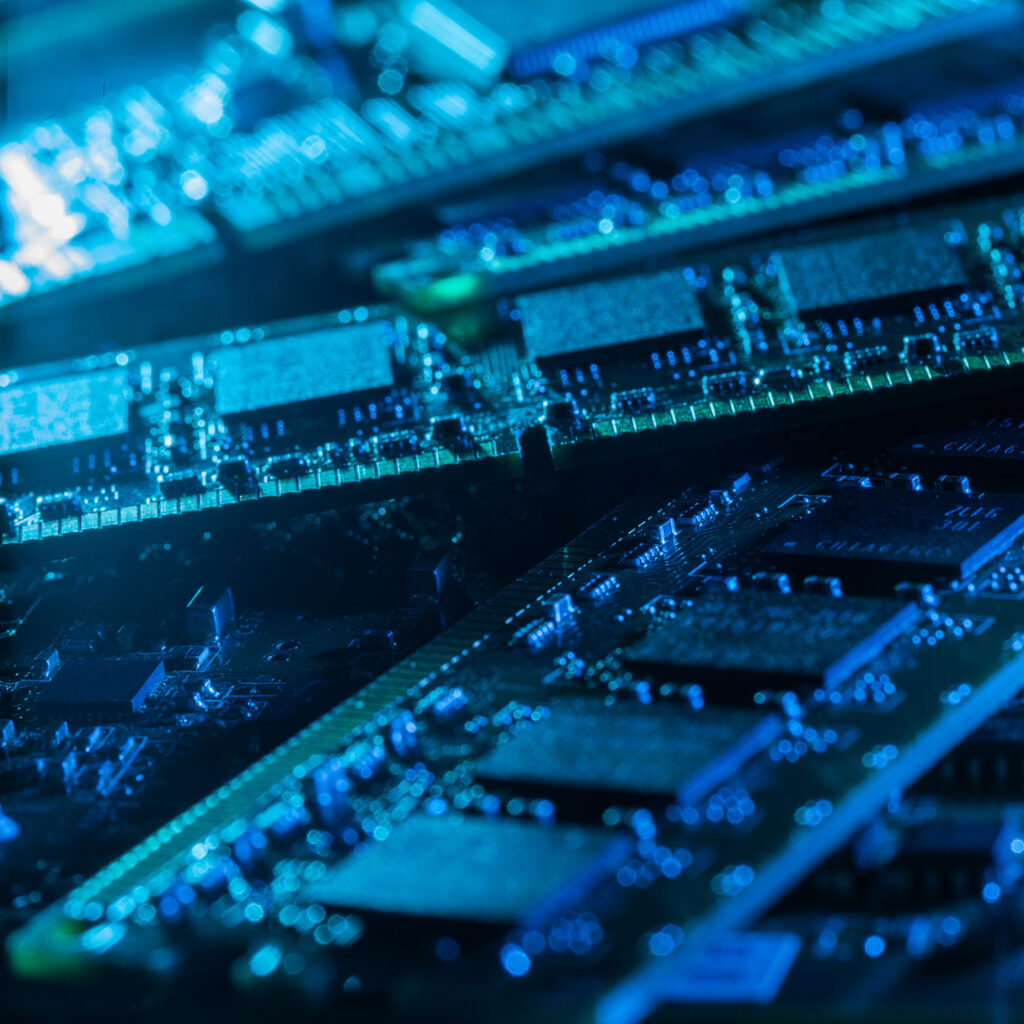

Automated Optical Inspection (AOI): Digital Eyes on Perfection

AOI technology allows us to detect even the smallest defects during the assembly process. This system, based on high-resolution cameras and advanced recognition algorithms, analyzes each board with millimetric precision, identifying anomalies in component placement or soldering.

X-Ray: Inside the Circuit, Beyond the Invisible

With X-ray technology, we can analyze the deepest layers of the circuit without compromising its integrity. This technique is essential for checking internal connections, such as solder joints in BGA (Ball Grid Array) components or other complex configurations that are not externally visible.

Get in Touch

Thanks to such an advanced quality control process, we are able to offer our clients flawless products, ready to face the most complex challenges. With EMC SRL, there are no compromises—every detail stands for excellence.